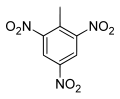

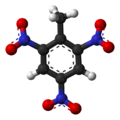

Trinitrotoluene

| Trinitrotoluene | |

|---|---|

|

|

|

2-methyl-1,3,5-trinitrobenzene

|

|

|

Other names

2,4,6-Trinitrotoluene,

TNT, Trilite, Tolite, Trinol, Trotyl, Tritolo, Tritolol, Triton, Tritone, Trotol, Trinitrotoluol, 2,4,6-Trinitromethylbenzene |

|

| Identifiers | |

| Abbreviations | TNT |

| CAS number | 118-96-7 |

| PubChem | 8376 |

| EC number | 204-289-6 |

| UN number | 0209 – Dry or wetted with < 30% water 0388, 0389 – Mixtures with trinitrobenzene, hexanitrostilbene |

|

SMILES

CC1=C(C=C(C=C1[N+](=O)[O-])[N+](=O)[O-])[N+](=O)[O-] =]

|

|

| Properties | |

| Molecular formula | C7H5N3O6 |

| Molar mass | 227.13 g/mol |

| Appearance | Pale yellow. Loose "needles" before melt-casting. A solid block after being poured into a casing. |

| Density | 1.654 g/cm3 |

| Melting point |

80.35 °C |

| Boiling point |

295 °C (decomposition) |

| Solubility in water | 0.13 g/L (20 °C) |

| Solubility in ether, acetone, benzene, pyridine | soluble |

| Explosive data | |

| Shock sensitivity | Insensitive |

| Friction sensitivity | Insensitive to 353 N |

| Explosive velocity | 6900 m/s |

| RE factor | 1.00 |

| Hazards | |

| MSDS | ICSC 0967 |

| EU Index | 609-008-00-4 |

| EU classification | Explosive (E) Toxic (T) Dangerous for the environment (N) |

| R-phrases | R2, R23/24/25, R33, R51/53 |

| S-phrases | (S1/2), S35, S45, S61 |

| NFPA 704 |

4

2

4

|

| Related compounds | |

| Related compounds | picric acid hexanitrobenzene |

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C, 100 kPa) |

|

| Infobox references | |

Trinitrotoluene (pronounced /ˌtraɪnaɪtrɵˈtɒljʉ.iːn/; famously known and abbreviated as TNT), or more specifically, 2,4,6-trinitrotoluene, is a chemical compound with the formula C6H2(NO2)3CH3. This yellow-colored solid is sometimes used as a reagent in chemical synthesis, but it is best known as a useful explosive material with convenient handling properties. The explosive yield of TNT is considered to be the standard measure of strength of bombs and other explosives. In chemistry, TNT is used to generate charge transfer salts.

Contents |

Preparation

Industrially, TNT is synthesized in a three-step process. First, toluene is nitrated with a mixture of sulfuric and nitric acid to produce mono-nitrotoluene or MNT. The MNT is separated and then renitrated to dinitrotoluene or DNT. In the final step, the DNT is nitrated to trinitrotoluene or TNT using an anhydrous mixture of nitric acid and oleum. Nitric acid is consumed by the manufacturing process, but the diluted sulfuric acid can be reconcentrated and reused. Subsequent to nitration, TNT is stabilized by a process called sulphitation, where the crude TNT is treated with aqueous sodium sulfite solution in order to remove less stable isomers of TNT and other undesired reaction products. The rinse water from sulphitation is known as red water and is a significant pollutant and waste product of TNT manufacture.[1]

Control of nitrogen oxides in feed nitric acid is very important because free nitrogen dioxide can result in oxidation of the methyl group of toluene. This reaction is highly exothermic and carries with it the risk of runaway reaction and explosion.

In the laboratory, 2,4,6-trinitrotoluene is produced by a two step process. A nitrating mixture of concentrated nitric and sulfuric acids is used to nitrate toluene to a mixture of mono- and di-nitrotoluene isomers, with cooling to maintain careful temperature control. The nitrated toluenes are separated, washed with dilute sodium bicarbonate to remove oxides of nitrogen, and then carefully nitrated with a mixture of fuming nitric acid and sulfuric acid. Towards the end of the nitration, the mixture is heated on a steam bath. The trinitrotoluene is separated, washed with a dilute solution of sodium sulfite and then recrystallized from alcohol.

Applications

TNT is one of the most commonly used explosives for military and industrial applications. It is valued because of its insensitivity to shock and friction, which reduces the risk of accidental detonation. TNT melts at 80 °C (176 °F), far below the temperature at which it will spontaneously detonate, allowing it to be poured as well as safely combined with other explosives. TNT neither absorbs nor dissolves in water, which allows it to be used effectively in wet environments. Additionally, it is stable compared to other high explosives.

Although blocks of TNT are available in various sizes (e.g. 250 g, 500 g, 1,000 g ), it is more commonly encountered in synergistic explosive blends comprising a variable percentage of TNT plus other ingredients. Examples of explosive blends containing TNT include:

- Amatex

- Amatol

- Ammonal

- Baratol

- Composition B

- Composition H6

- Cyclotol

- Ednatol

- Hexanite

- Minol

- Octol

- Pentolite

- Picratol

- Tetrytol

- Torpex

- Tritonal

Explosive character

It is a common misconception that TNT and dynamite are the same, or that dynamite contains TNT. In fact, whereas TNT is a specific chemical compound, dynamite is an absorbent mixture soaked in nitroglycerin that is compressed into a cylindrical shape and wrapped in paper.

Upon detonation, TNT decomposes as follows:

- 2 C7H5N3O6 → 3 N2 + 5 H2O + 7 CO + 7 C

The reaction is exothermic but has a high activation energy. Because of the production of carbon, TNT explosions have a sooty appearance. Because TNT has an excess of carbon, explosive mixtures with oxygen-rich compounds can yield more energy per kilogram than TNT alone. During the 20th century, amatol, a mixture of TNT with ammonium nitrate was a widely used military explosive.

Detonation of TNT can be done using a high velocity initiator or by efficient concussion.[2]

For many years, TNT used to be the reference point for the Figure of Insensitivity. TNT has a rating of exactly 100 on the F of I scale. However, the reference has since been changed to a more sensitive explosive called RDX, which has an F of I of 80.

Energy content

TNT contains 4.6 megajoules per kilogram. The energy density of TNT is used as a reference-point for many other types of explosives, including nuclear weapons, the energy content of which is measured in kilotons (~4.184 terajoules) or megatons (~4.184 petajoules) of TNT equivalent.

For comparison, gunpowder contains 3 megajoules per kilogram, dynamite contains 7.5 megajoules per kilogram, and gasoline contains 47.2 megajoules per kilogram (though gasoline requires an oxidant, so "gasoline + O2" mixture contains only 10.4 megajoules per kilogram).

History

TNT was first prepared in 1863 by German chemist Joseph Wilbrand[3] and originally used as a yellow dye. Its potential as an explosive was not appreciated for several years mainly because it was so difficult to detonate and because it was less powerful than alternatives. TNT can be safely poured when liquid into shell cases, and is so insensitive that in 1910, it was exempted from the UK's Explosives Act 1875 and was not considered an explosive for the purposes of manufacture and storage.

The German armed forces adopted it as a filling for artillery shells in 1902. TNT-filled armour-piercing shells would explode after they had penetrated the armour of British capital ships, whereas the British lyddite-filled shells tended to explode upon striking armour, thus expending much of their energy outside the ship. The British started replacing lyddite with TNT in 1907. TNT is still widely used by the United States military and construction companies around the world. The majority of TNT currently used by the US military is manufactured by Radford Army Ammunition Plant near Radford, Virginia.

Safety and toxicity

TNT is poisonous, and skin contact can cause skin irritation, causing the skin to turn a bright yellow-orange color. During the First World War, munition workers who handled the chemical found that their skin turned bright yellow, which resulted in their acquiring the nickname "canary girls" or simply "canaries."

People exposed to TNT over a prolonged period tend to experience anemia and abnormal liver functions. Blood and liver effects, spleen enlargement and other harmful effects on the immune system have also been found in animals that ingested or breathed trinitrotoluene. There is evidence that TNT adversely affects male fertility, and TNT is listed as a possible human carcinogen[4]. Consumption of TNT produces red urine through the presence of breakdown products and not blood as sometimes believed.[5]

Some military testing grounds are contaminated with TNT. Wastewater from munitions programs including contamination of surface and subsurface waters may be colored pink because of the presence of TNT. Such contamination, called "pink water", may be difficult and expensive to remedy.

TNT is prone to exudation of dinitrotoluenes and other isomers of trinitrotoluene. Even small quantities of such impurities can cause such effect. The effect shows especially in projectiles containing TNT and stored at higher temperatures, e.g. during summer. Exudation of impurities leads to formation of pores and cracks (which in turn cause increased shock sensitivity). Migration of the exudated liquid into the fuze screw thread can form fire channels, increasing the risk of accidental detonations; fuze malfunction can result from the liquids migrating into its mechanism.[6]

See also

- TNT equivalent

- Explosives used during WW II

- Dynamite (Difference from TNT)

- IMX-101

References

- ↑ Urbanski, Tadeusz (1964). Chemistry and Technology of Explosives. 1. Pergamon Press. pp. 389–91. ISBN 0-0801-0238-7.

- ↑ Merck Index, 13th Edition, 9801.

- ↑ J. Wilbrand (1863). "Notiz über Trinitrotoluol". Annalen der Chemie und Pharmacie 128 (2): 178–179. doi:10.1002/jlac.18631280206.

- ↑ Toxicological Profile for 2,4,6-Trinitrotoluene

- ↑ "2,4,6-Trinitrotoluene". Agency for Toxic Substances and Disease Registry. http://www.atsdr.cdc.gov/ToxProfiles/tp81-c2.pdf. Retrieved 2010-05-17.

- ↑ http://books.google.com/books?id=9tIQDn2uZz4C&pg=PA11&dq=polymer+bonded+explosives&lr=&num=50&as_brr=3&cd=1#v=onepage&q=polymer%20bonded%20explosives&f=false

External links

- Video showing detonation of 50 tons of TNT in 1963 during Anglo-Australian Operation Blowdown

- Video showing the five 20 ton underground blasts of Project Dugout in 1965

- Video showing the shockwave and typical black smoke cloud from detonation of 160 kilograms of pure TNT

- Video showing detonation of 453 metric tons of TNT in 1965 Operation Sailor Hat - note shockwave and black smoke residue

- Video of demolition training using half pound blocks of pure TNT

- NLM Hazardous Substances Databank – Trinitrotoluene